I knew I'd seen something similar, but couldn't remember where.

I'm no engineer, but I'm thinking that moving the ball position relative to the wishbone is going to create more of a twisting load on the wishbone and the ball joint plate, which they're not really designed to take.

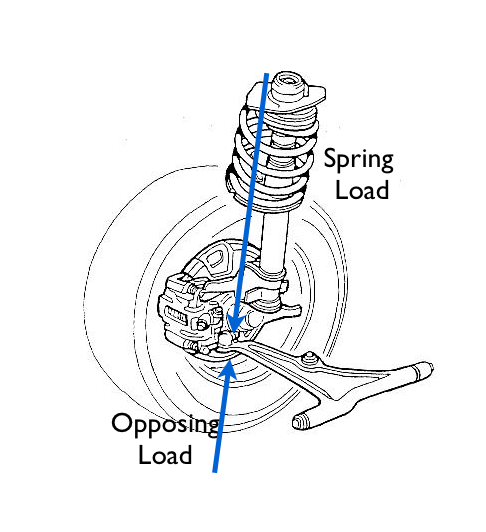

Instead of the spring pushing down and the loads from the weight of the car on the road pushing up through the ball joint in line - in the centre of the wheel, I think they might be offset with the balljoint out of line with the spring load - is that the King Pin Axis? (probably using the wrong terms but hopefully you know what I mean)….

So the force of the spring is still on the centre of the wheel, but the upward force is more towards the back of the wheel.

I don't know if it's strong enough or going to bend when you go bouncing over a kerb at high speed. I was thinking I would need to strengthen the wishbone around the balljoint to help, with the audi ball joint, although on the other hand it's designed for a car that's 50% heavier than the A1 chassis. The advantage of your solution is you're using the standard pin size and don't need to modify the hub.

I guess you'll find out the first time you take it out testing - I'm sure that's a better guide than my guesswork!