|

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to.

Messages - RobT

Pages: 1 2 3 [4] 5 6 ... 9

46

« on: November 09, 2013, 09:19:42 am »

My exhaust manifold is ceramic coated 4 layers inside and out. As tony said, this is to keep the gas hot, low viscosity, to speed its removal from the car. Wrc cars insulate the whole exhaust and i heard a story of mcraes focus setting fire to a marshalls trousers as he walked past the tailpipe.

Coolant hoses are a minor thing i would suggest.

Use of ceramics on head and pistons is an interesting one. You want to turn as much burn energy into piston motion as you can, and heat loss is energy loss. So you would think insulate everything....But.......if you do this, detonation can result. So i have never gone down this route with a race engine for uk use. Desert racing with low revving chugger engines is another matter....

Goid topic

47

« on: November 09, 2013, 09:14:02 am »

I like this subject, raced 2stroke bikes for many years and heat management was exerything.

Black rads, inside snd outside, are better to radiate heat. But the design is probably more critical, especially the fin vortices, fin count, and effective ducting. And need to keep fins in good condition with no crap in there.

Re inlet manifold, as this is bolted to a big heat source, the head, conduction heating is most significant. I have a phenolic insulator gasket between the head and my tbs to try and reduce heating of inlet tract. I suppose you could polish the outside to try and reflect engine bay heat. For a boosted engine, maybe black inside and out would be an idea to reduce intake air heat.

48

« on: November 08, 2013, 09:12:17 pm »

Water temps no, oil temps yes. Cooling is always welcome, less high drag radiator intakes needed, more speed!

49

« on: November 07, 2013, 08:39:14 pm »

Welcome sir

50

« on: November 03, 2013, 09:22:16 pm »

Fair enough, sounds like you have thought it through. I guess i'm cautious for things like this. Its never good if the engine comes out the front of the car when you hit the brakes lol.

How about an ali extrusion with cnc'd ends bolted/riveted/glued in?

51

« on: November 03, 2013, 09:08:21 pm »

Like this nige. Have spotted before that they are sometimes not greased well. Is that redline high temp grease?

52

« on: November 03, 2013, 09:06:07 pm »

Ali would worry me for this if the front engine mount sits in it. Could easily vibration-crack. T45 would be the way to go imo.

53

« on: October 26, 2013, 07:37:08 pm »

54

« on: October 26, 2013, 07:30:21 pm »

still has rear beam due to regs, but they mount them solid and sometimes fit some very sophisticated damper arrangements, have seen two different designs

edit - read the article again - rear has coilovers and turrets, but still using beam arrangement

55

« on: October 26, 2013, 07:28:24 pm »

Metal plus paint on passenger side floor of my ibiza is 1.3mm (just measured with mic, in region where floor bungs are)

56

« on: October 26, 2013, 07:13:53 pm »

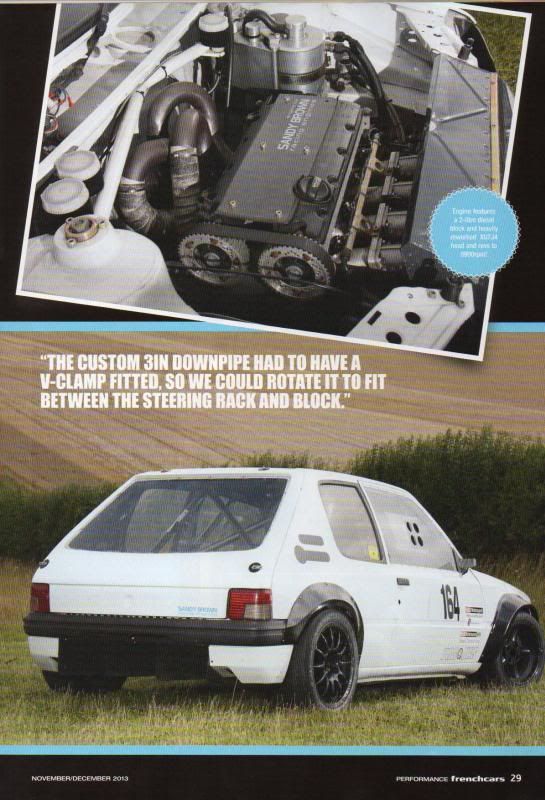

I have 2 sets of 48mm secondaries going through there so even a 3" should be ok, but it depends on the angle

57

« on: October 26, 2013, 07:03:30 pm »

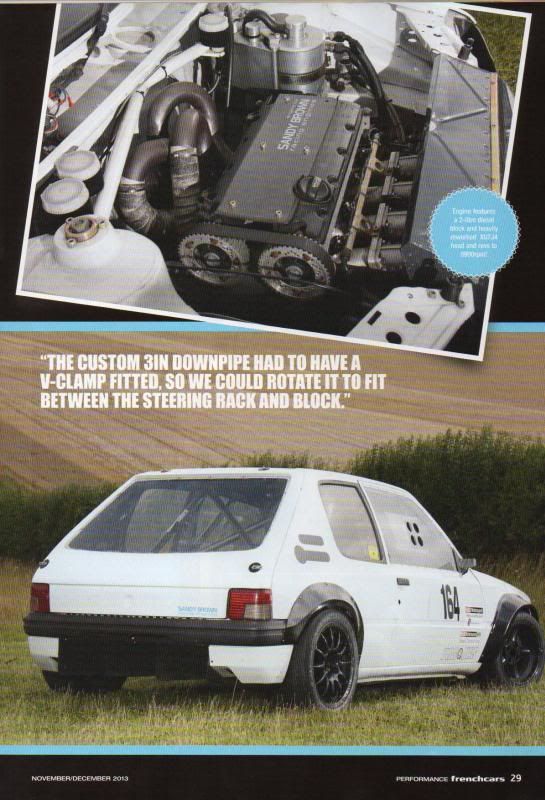

Good article in current Performance French Cars (nov/dec 2013) p24-30 Beast of a machine. 280+ hp Sandy Brown engine, 191ftlb, 1997cc (85mm bore x 88mm stroke), 714kg with fluids.

58

« on: October 26, 2013, 06:55:34 pm »

Shouldnt be necessary. Fit a expansion 'slip' joint under where the shifter us so the exhaust can grow in length when its get hot, mine has marks suggesting ad much as an inch movement! Then the manifold doesnt bend and foul the tunnel/ rack when hot.

59

« on: October 26, 2013, 06:21:09 pm »

The reverse flywheel is a daft idea. Bin it and fit an 02a setup.

60

« on: October 26, 2013, 06:17:30 pm »

I'd go for 1.2mm.

Pages: 1 2 3 [4] 5 6 ... 9

| |